MMT gives you the answers you need on material properties, performance, strength, durability and corrosion covering metals, composites, and polymers.

Our materials testing capabilities include materials selection, materials performance and failure analysis, using both destructive and non-destructive testing. Our testing solutions are used to evaluate and verify products and materials for properties, performance, integrity and safety for our clients.

We continually invest in our technology and our team. Led by our Senior Engineer, Professor and Founder Dr. Thomas Shelton, PhD with expertise in chemical, material, mechanical and electrical engineering. We can expedite analysis turnaround times with our facilities which include in-house testing labs with experienced technicians and a machining capabilities to provide fast sample preparation.

Services include routine and customized testing and evaluations to recognized standards (NSF/ANSI, ASTM, etc.), failure analysis, method and protocol development, and consulting. Complete traceability and documentation (Chain of custody) performed.

We provide the following materials information:

- composition

- chemical properties

- structure

- mechanical properties

- physical properties

We work with traditional metals, advanced alloys and Polymers.

Our testing includes:

- Elemental Analysis

- Relative Elemental Analysis

- Corrosion

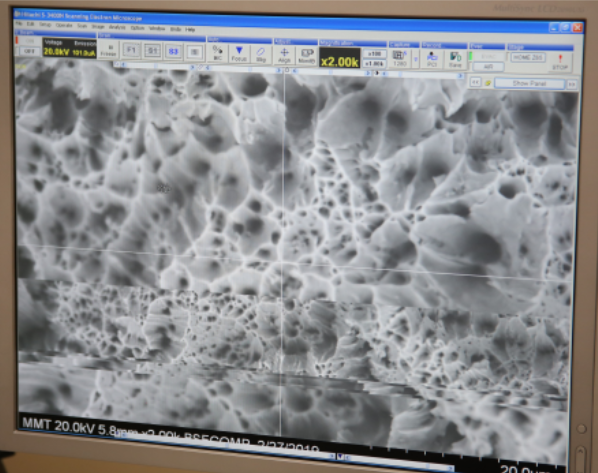

- Scanning Electron Microscopy (SEM)

- Energy Dispersive Spectrometry (EDS)

- Hardness

- Metallography

- Macroscopic evaluation

- Microscopic evaluation

- Material identification

- Remelt

- Weld Testing

Uses:

- Material identification

- Composition

Support Services:

- Sample Preparation

- Photographic Documentation

- Remelt Capability

Elemental Testing:

MMT has the capability of determining composition (chemistry) using one of two methods:

Elemental

Optical Emission Spectroscopy (OES)

MMT uses a spark source to excite energy, which causes electrons in the sample to emit light which allows us to provide accurate metal elemental composition.

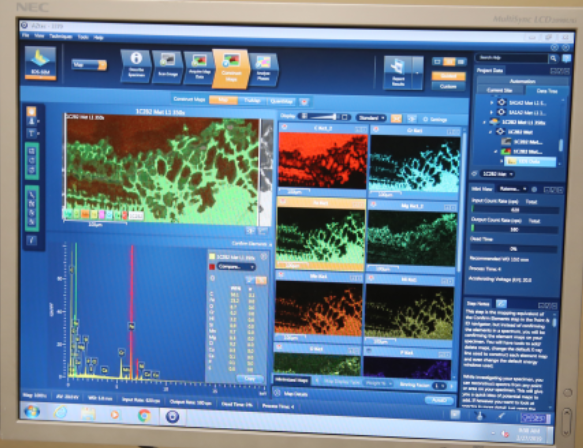

Relative Elemental

Energy Dispersive Spectroscopy (EDS)

In conjunction with our scanning electron microscope (SEM), the EDS uses a scanning electron beam to excite atoms of an unknown material. The x-ray emitted from the sample, characterizes the elemental composition.

Typical uses for EDS include:

- Foreign material analysis

- Corrosion evaluation

- Coating composition analysis

- Rapid material alloy identification

- Small component material analysis

- Phase identification and distribution